Common Gasoline Fuel Injectors Part 2 - Direct Fuel Injectors (GDI/FSI)

Posted by Big Dawg Diesel on Nov 25th 2024

Direct Fuel Injectors (GDI/FSI): Revolutionizing Engine Performance and Efficiency

Direct fuel injectors, commonly referred to as Gasoline Direct Injection (GDI) or Fuel Stratified Injection (FSI), represent a leap forward in fuel delivery technology. By injecting fuel directly into the combustion chamber, these injectors enable precise fuel control, improving performance, efficiency, and emissions. In this blog, we’ll delve into how direct fuel injectors work, their advantages, potential drawbacks, and why they’re a key innovation in modern automotive engineering.

What Are Direct Fuel Injectors?

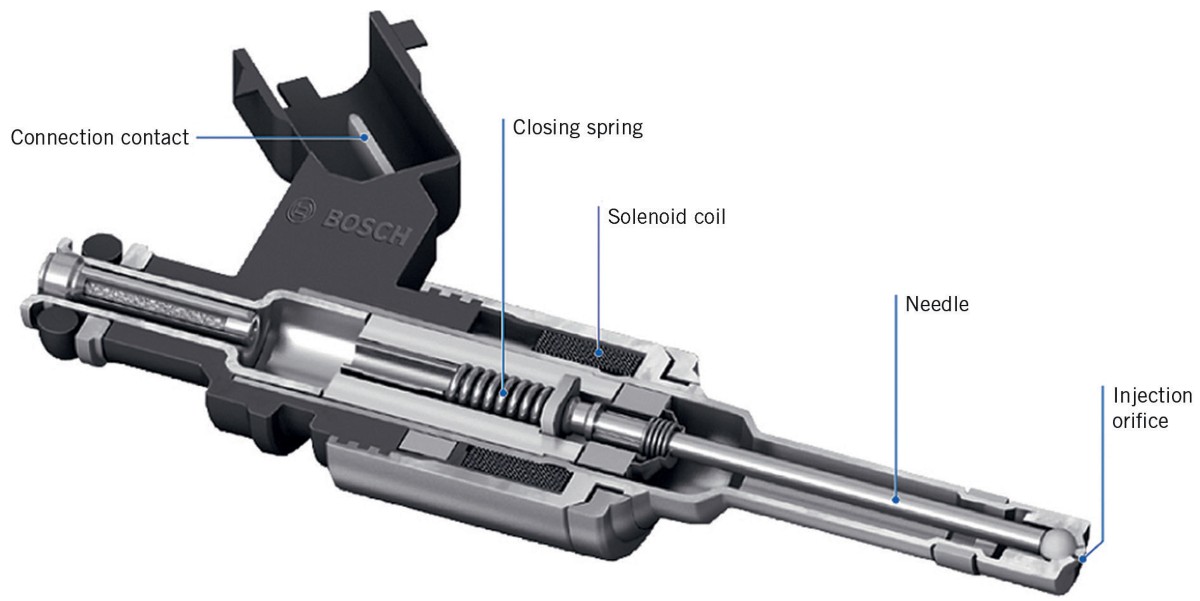

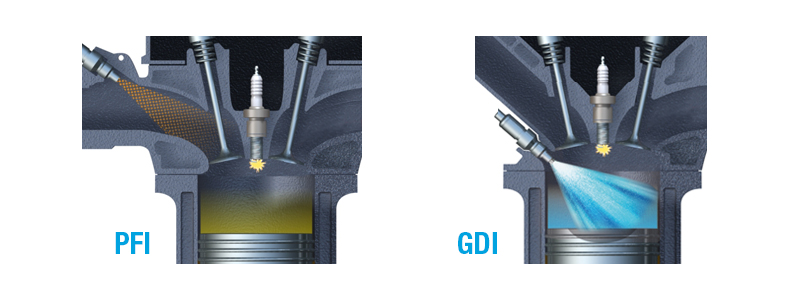

Direct fuel injectors are an advanced type of fuel delivery system where fuel is sprayed directly into the engine’s combustion chamber rather than into the intake manifold, as with port fuel injection. This approach ensures better atomization of fuel, precise mixing with air, and controlled combustion.

GDI systems are highly responsive, adapting the fuel delivery to real-time driving conditions. These injectors are commonly used in modern gasoline engines and are a staple in turbocharged and high-performance vehicles.

How Do Direct Fuel Injectors Work?

Direct fuel injectors operate as part of a GDI system that consists of a high-pressure fuel pump, fuel rail, and a series of sensors. Here’s how they function:

- Fuel Delivery: The fuel pump pressurizes gasoline to levels significantly higher than in port injection systems (often exceeding 2,000 psi), sending it to the injectors.

- Precision Timing: The engine control unit (ECU) uses data from sensors (such as throttle position, engine speed, and air intake temperature) to determine the precise moment and duration for injection.

- Injection Process: The injector sprays a fine mist of fuel directly into the combustion chamber. The atomized fuel mixes with air for optimal combustion. This process occurs in milliseconds, ensuring the right amount of fuel for every driving condition.

- Combustion Optimization: Direct injection allows for stratified charge combustion, where a rich air-fuel mixture is concentrated near the spark plug and a leaner mixture fills the rest of the chamber. This design maximizes efficiency and minimizes emissions.

Advantages of Direct Fuel Injectors

Direct fuel injectors offer numerous benefits that make them a preferred choice for manufacturers seeking improved engine performance and efficiency:

- Enhanced Fuel Efficiency:

- GDI systems deliver fuel more precisely, reducing waste and improving fuel economy. This is particularly beneficial during low-load conditions like idling or cruising.

- Increased Power Output:

- By injecting fuel directly into the combustion chamber, GDI systems create a cooler charge, allowing for higher compression ratios. This results in more power from smaller engines, a concept known as engine downsizing.

- Reduced Emissions:

- GDI engines produce fewer CO2 emissions due to optimized fuel combustion. The precise air-fuel ratio helps lower unburned hydrocarbons and carbon monoxide.

- Improved Throttle Response:

- Direct injection delivers fuel more rapidly and accurately, enhancing responsiveness and drivability.

- Compatibility with Turbocharging:

- GDI systems pair well with turbochargers, as they help maintain engine performance while reducing fuel consumption.

Challenges and Drawbacks

Despite their many advantages, direct fuel injectors come with challenges that manufacturers and owners need to address:

- Carbon Buildup:

- Unlike port injection systems, GDI injectors spray fuel directly into the combustion chamber, bypassing the intake valves. This can lead to carbon deposits forming on the valves, which affects performance over time. Regular maintenance or the use of dual-injection systems can mitigate this issue.

- Higher Maintenance Costs:

- The complexity of GDI systems, including high-pressure fuel pumps and injectors, can lead to increased maintenance and repair expenses compared to traditional systems.

- Potential for Injector Clogging:

- Direct injectors operate under extreme pressure, making them more susceptible to clogging from impurities in the fuel. Using high-quality gasoline and periodic cleaning can help alleviate this issue.

- Noise:

- GDI engines are often louder due to the high pressure at which the fuel is delivered. Advanced engineering and insulation have minimized this drawback in modern vehicles.

Applications and Evolution

GDI technology is widely used across domestic and foreign manufacturers, with notable examples including:

- Domestic: Ford EcoBoost engines, GM’s Ecotec engines.

- Foreign: Toyota’s D4-S, BMW’s N55, and Volkswagen’s TSI engines.

Many automakers now incorporate dual-injection systems, combining the benefits of GDI and port injection. For instance, Toyota’s D4-S system uses both methods to optimize performance and reduce carbon buildup.

Additionally, GDI systems are central to hybrid and plug-in hybrid vehicles, further enhancing their efficiency and environmental benefits.

Maintenance Tips for GDI Engines

To ensure your GDI system operates efficiently, consider the following maintenance practices:

- Regular Fuel System Cleaning: Use GDI-specific fuel additives or professional cleaning services to prevent injector clogging and carbon buildup.

- High-Quality Fuel: Premium gasoline with detergents helps reduce impurities that can harm the injectors.

- Periodic Inspection: Schedule routine inspections to catch potential issues early.

Conclusion

Direct fuel injectors have revolutionized gasoline engine technology, offering unmatched precision and efficiency. While they present some maintenance challenges, their benefits in fuel economy, power, and emissions outweigh the drawbacks. As automakers continue to refine this technology and integrate it with hybrid systems, GDI injectors will remain a critical component in the pursuit of cleaner, more efficient vehicles.

Whether you're a car enthusiast, a mechanic, or simply a curious driver, understanding direct fuel injectors can give you a deeper appreciation for the engineering behind modern engines. By staying informed and maintaining your vehicle, you can enjoy the many advantages GDI technology offers for years to come.